Next generation tooling materials to redefine the art of making plugs, patterns, models and molds.

Modelo

Modelling Pastes & Putties

Low density, machine extrudable two component modelling pastes featuring excellent machinability, surface finish and sag resistance for patterns & plugs

- Cured densities as low as 0.60 g/cc

- Sag resistance upto 30mm on vertical surfaces

- Excellent machinability and surface finishes

Novogel

Epoxy Tooling Gelcoats

High performance two component epoxy gelcoats over a wide range of temperature resistance

- Sprayable without the use of solvents

- Temperature resistance upto 230 C

- Highly polishable or highly abrasion resistant surfaces possible

Eporun + Epocur

Tooling Resin Systems

Two-component epoxy laminating resin systems available in a wide range of viscosities, temperature resistance, process suitability and pot life

- Temperature resistance upto 230C

- Perfectly suited to vacuum infusion as well as hand lamination

- Available in a range of pot lives

Novocast

Epoxy Casting Systems

High temperature casting systems simplifying the manufacture of a variety of molds and toolings

- Easily pourable with excellent levelling properties

- Temperature resistance upto 230 C

- Pinhole free, excellent surface finishes possible

Product Spotlight

Product Spotlight

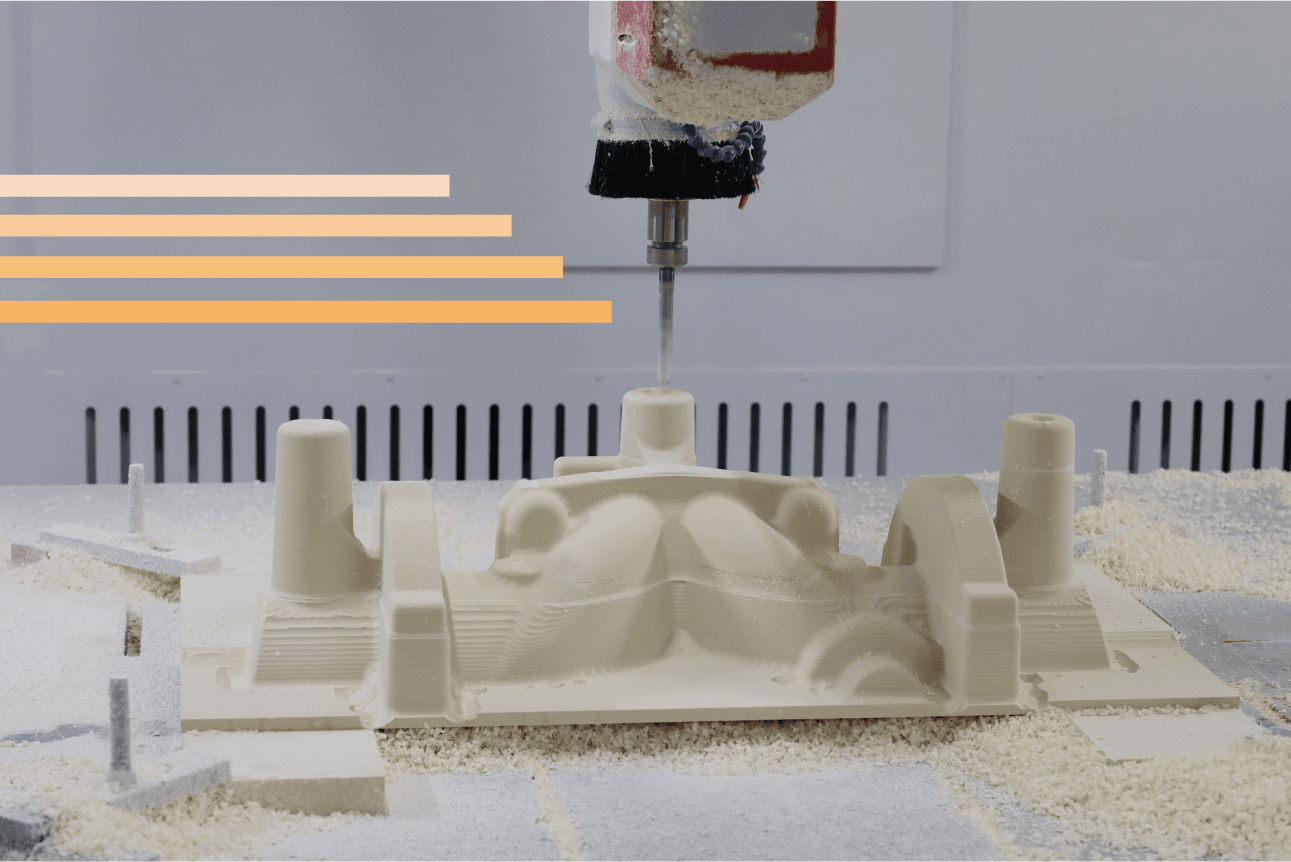

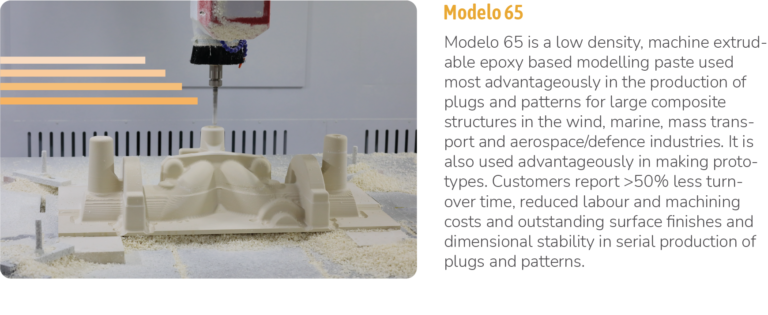

Modelo 65

Modelo 65 is a low density, machine extrudable epoxy based modelling paste used most advantageously in the production of plugs and patterns for large composite structures in the wind, marine, mass transport and aerospace/defence industries. It is also used advantageously in making prototypes. Customers report >50% less turnover time, reduced labour and machining costs and outstanding surface finishes and dimensional stability in serial production of plugs and patterns

Product Spotlight

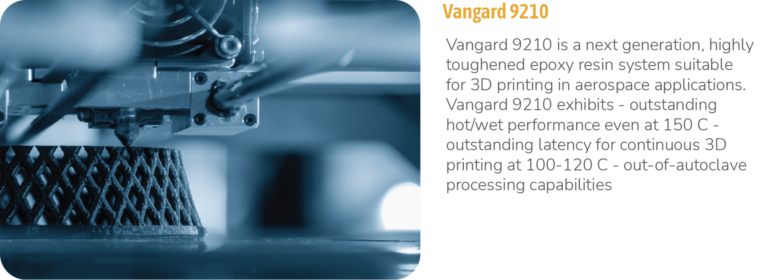

Vangard 9210

Vangard 9210 is a next generation, highly toughened epoxy resin system suitable for 3D printing in aerospace applications. Vangard 9210 exhibits - outstanding hot/wet performance even at 150 C - outstanding latency for continuous 3D printing at 100-120 C - out-of-autoclave processing capabilities

What Sets us Apart